Extrusion of

thermopolymers

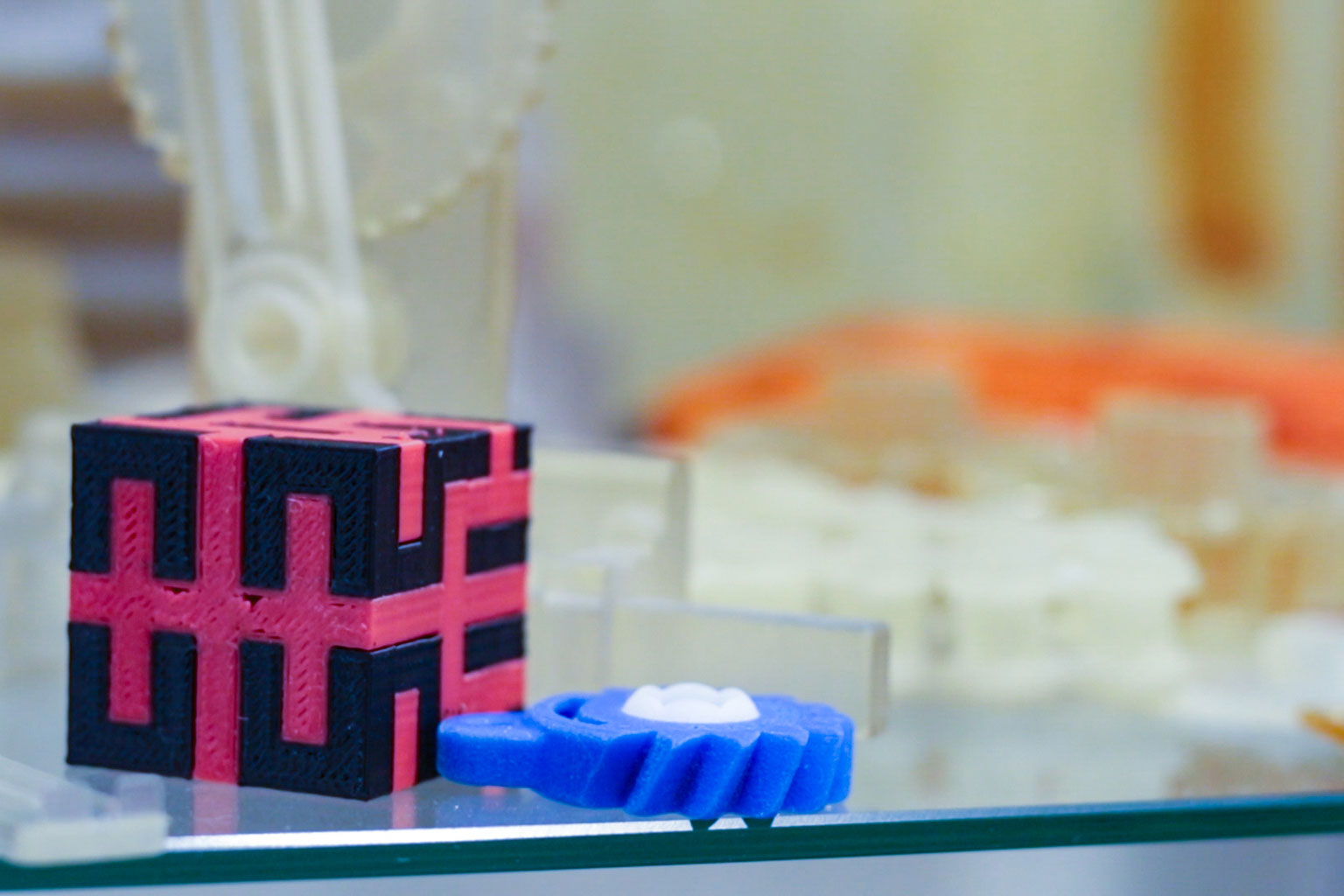

Conceptual prototypes

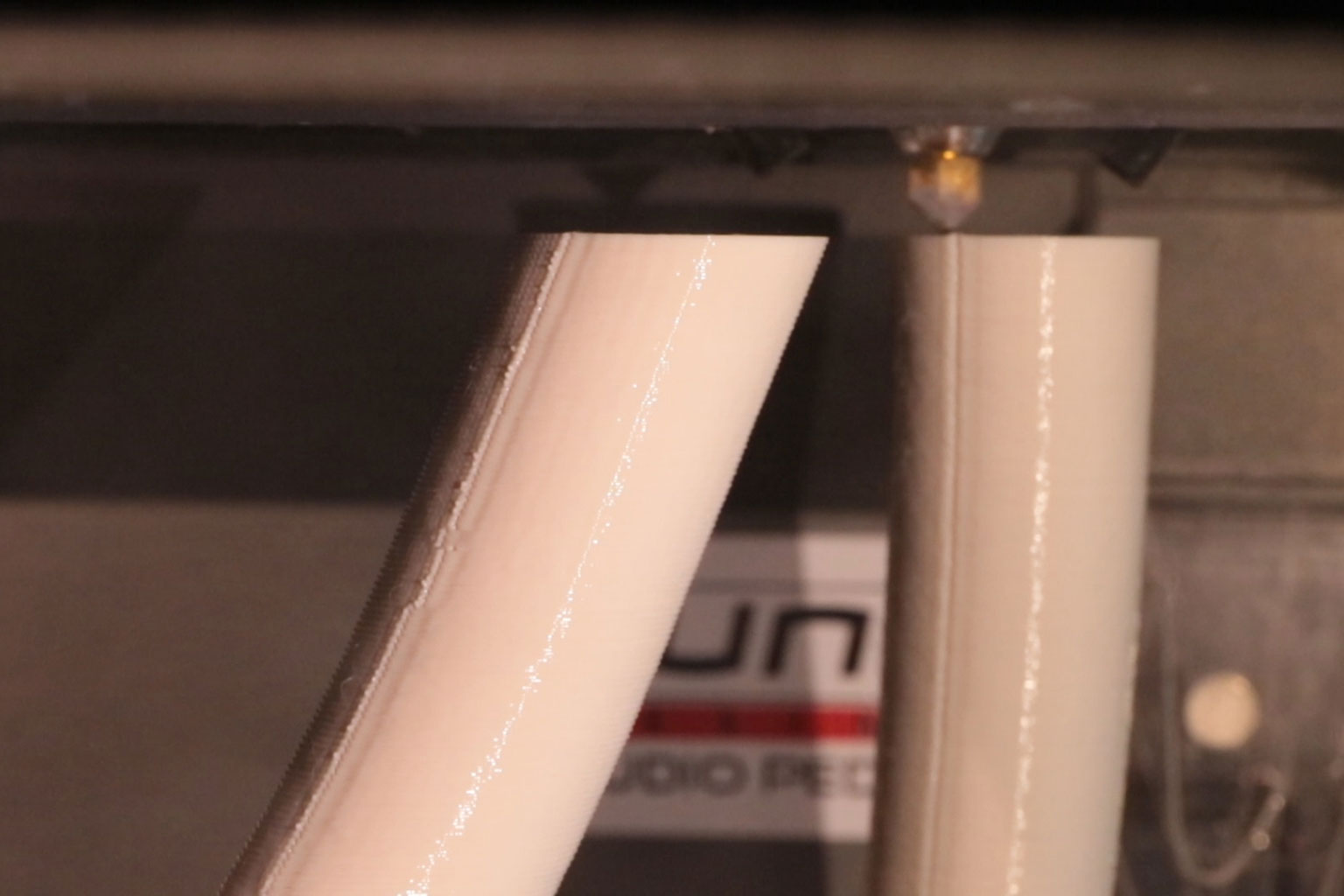

High-performance functional elements.

Technical Data

| Materials | PLA | TOUGH | PETG | ASA | ABS | PC |

|---|---|---|---|---|---|---|

| Tensile strenght MPa Metodo ASTM D638 |

62 | 35 | 44 | 49 | 31-26 (Ultimate) |

57.3 |

| Elogation at break % Metodo ASTM D638 |

>4.4 | >52.7 | >3.8 | >6 | >7-2 | 5.2 |

| Modulus of elasticity MPa Metodo ASTM D638 |

3600 | 2800 | 1900 | 2100 | 2230 (XZ) 2180 (ZX) |

2250 |

| Flexural Modulus MPa Metodo ASTM D790 |

2600 | 2600 | 2000 | 2300 | 2060 (XZ) 1760 (ZX) |

N.A |

| Notched Impact Strenght J/m Metodo ASTM D256 |

32 | 220 | 18.7 | 140 | 128-300 | 76.8 |

| Heat Deflection Temp. °C 0,45 MPa Metodo ASTM D648 |

52-49 | 53-49 | 70 | 96 | 82 | 142 |

| Materials | PC-ABS FR | NYLON | NYLON 6 C.F. | NYLON 12 C.F. | ULTEM 1010 | ULTEM 9085 |

|---|---|---|---|---|---|---|

| Tensile strenght MPa Metodo ASTM D638 |

60 (ISO 527) |

66 | 110 | 66 | 81-37 (Ultimate) |

69-42 (Ultimate) |

| Elogation at break % Metodo ASTM D638 |

>50 (ISO 527) |

>10 | N.A. | N.A. | 3.3 - 2.0 | 5.8 - 2.2 |

| Modulus of elasticity MPa Metodo ASTM D638 |

2850 (ISO 527) |

2200 | 7600 | 6000 | 2770 (XZ) 2200 (ZX) |

2150 (XZ) 2270 (ZX) |

| Flexural Modulus MPa Metodo ASTM D790 |

N.A. | 1700 | N.A. | N.A. | 2820 (XZ) 2230 (ZX) |

2300 (XZ) 2050 (ZX) |

| Notched Impact Strenght J/m Metodo ASTM D256 |

N.A. | 187 | N.A. | N.A. | 41-24 | 120-48 |

| Heat Deflection Temp. °C 0,45 MPa Metodo ASTM D648 |

N.A. | 91 | 184 | 154 | 216 | 153 |

| Impact Strenght Charpy methos 23°C ISO 179 (kJ/m2) |

42.5 | N.A. | N.A. | N.A. | N.A. | N.A. |

| Vicat Softening Temp ISO 306 |

104 | N.A. | N.A. | N.A. | N.A. | N.A. |

| Flammability Rating UL94 |

V0 | N.A. | N.A. | N.A. | V0 | V0 |

| Glass Transition Temp. (Tg °C) | N.A. | N.A. | N.A. | N.A. | 209 | 177 |

| Bio Compatibility Certification USP CLass |

N.A. | N.A. | N.A. | N.A. | VI | VI |